Learn more about our workflow and capabilities

[dt_timeline title=”Tst” spy=”uk-animation-scale-up” scroll_delay=”3″][dt_timeline_item][mvc_infobox title_color=”#000000″ info_title=”Productive Facilities” title_size=”30″ image_id=”1797″ image_size=”200″]

The productive facilities are grouped in 3 sections:

[/mvc_infobox]

Section 1: 4000m²

Section 2: 2200m²

Section 3: 1800m²

Machining shop, welding shop and pre-assembly hall. ext 4.000m2 (9 bridge crane units. from 8.000/32.000 Kg each)

Assembly and machinery test. Ext. 2.200m2 (2 bridge crane units 16.000 Kg each)

Sheet metal shop (folding, bending and welding) . Ext. 1.800m2 (5 bridge crane units from 5.000/16.000 Kg each)

[/dt_timeline_item][dt_timeline_item position=”right”][mvc_infobox title_color=”#000000″ info_title=”Welded Components” title_size=”30″ image_id=”1788″ image_size=”200″][/mvc_infobox]

Every welded structural component in our equipment are built in our facilities by highly qualified welders by means of MAG-MIG-TIC welding processes.

The frames of our conveyors, feeders, shredders, and other heavy size equipment are welded from structural steel previously cutted by plasma or laser means and precisely shaped by cold forming.

[/dt_timeline_item][dt_timeline_item][mvc_infobox title_color=”#000000″ info_title=”Welded Rotary Drums” title_size=”30″ image_id=”1788″ image_size=”200″][/mvc_infobox]

DSG builds large size welded rotary drums up to 100Tm for some of our equipments, with our in-house developed methods , being such components assembled ensuring high precision and close concentricity tolerances.

[/dt_timeline_item][dt_timeline_item position=”right”][mvc_infobox title_color=”#000000″ info_title=”Welded Frames” title_size=”30″ image_id=”1788″ image_size=”200″][/mvc_infobox]

Most of our equipment is assembled on high resistance welded steel frames ensuring high dimensional precision.

[/dt_timeline_item][dt_timeline_item position=”right”][mvc_infobox title_color=”#000000″ info_title=”Hoppers-Silos-Welded Connection Chutes” title_size=”30″ image_id=”1799″ image_size=”200″][/mvc_infobox]

[/dt_timeline_item][dt_timeline_item][mvc_infobox title_color=”#000000″ info_title=”Frames & Components Machining” title_size=”30″ image_id=”1788″ image_size=”200″][/mvc_infobox]

For those components and frames requiring precision machining, we have big size CNC Lathe, CNC Mills and machining center, which ensures the smooth perfor-mance, endurance and reliability of our products during operation, allowing the repeatability on spare parts with easy replacement.

[/dt_timeline_item][dt_timeline_item position=”right”][mvc_infobox title_color=”#000000″ info_title=”Rotary Component Machining” title_size=”30″ image_id=”1804″ image_size=”200″][/mvc_infobox]

For those big size rotating components, we have big size precision lathe and mills to ensure reliable and smooth performance of the products in operation.

[/dt_timeline_item][dt_timeline_item][mvc_infobox title_color=”#000000″ info_title=”Gearbox Machining” title_size=”30″ image_id=”1796″ image_size=”200″][/mvc_infobox]

We machine the frames of our own high power specially designed gearboxes and other special equipment like shredders, ball mills, extruders, etc.

[/dt_timeline_item][dt_timeline_item position=”right”][mvc_infobox title_color=”#000000″ info_title=”Gear Machining” title_size=”30″ image_id=”1802″ image_size=”200″][/mvc_infobox]

For parallel or helical teeth gears, external or internal module 25 up to diameter 4.000mm

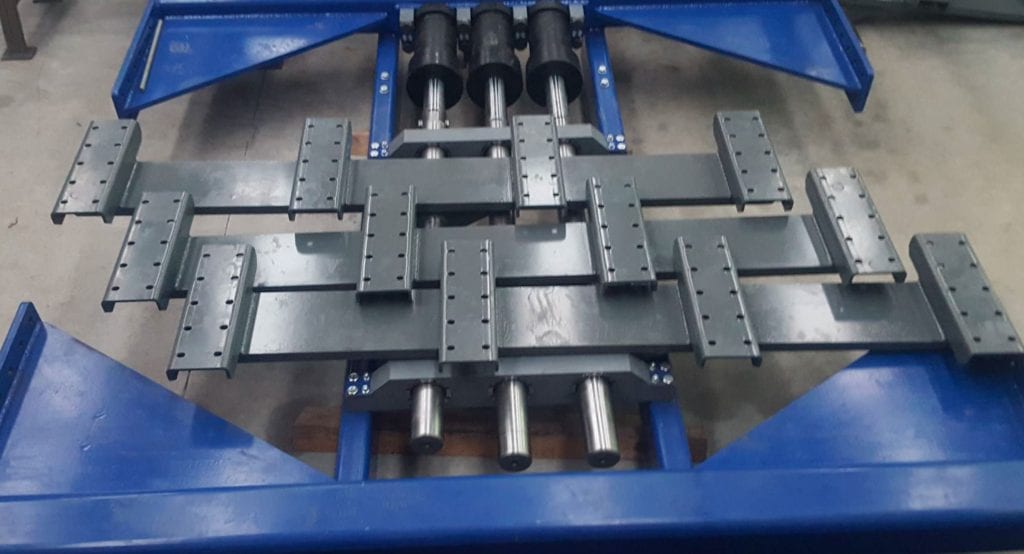

[/dt_timeline_item][dt_timeline_item][mvc_infobox title_color=”#000000″ info_title=”Complex Mechanical Assembling” title_size=”30″ image_id=”1796″ image_size=”200″][/mvc_infobox]

By means of highly skilled mechanics we assemble all the shafts, bearings, plates, transmission and all required elements following our internal best practice proce-dures or customer specifications.

[/dt_timeline_item][dt_timeline_item position=”right”][mvc_infobox title_color=”#000000″ info_title=”General Mechanical Assembling” title_size=”30″ image_id=”1796″ image_size=”200″][/mvc_infobox]

Our modular building philosophy ensures perfect fitting of the transmission elements in low time.

[/dt_timeline_item][dt_timeline_item][mvc_infobox title_color=”#000000″ info_title=”Gearbox Mechanical Assembling” title_size=”30″ image_id=”1788″ image_size=”200″][/mvc_infobox]

Our qualified and skilled mechanics perform the assembly of specially designed gear boxes, ensuring our own capability for post-sale service.

[/dt_timeline_item][dt_timeline_item position=”right”][mvc_infobox title_color=”#000000″ info_title=”Direct Drive Large Rotary Machinery Assembling” title_size=”30″ image_id=”1788″ image_size=”200″][/mvc_infobox]

Direct drive is our best approach for “keep-it-simple” and reliable for the big size rotary drums in some of our products.

[/dt_timeline_item][dt_timeline_item][mvc_infobox title_color=”#000000″ info_title=”Large Machinery Assembling” title_size=”30″ image_id=”1788″ image_size=”200″][/mvc_infobox]

DSG has developed an internal know-how and tooling for big size equipment assembly developed from our expertise manufacturing big size bulk material convey-ing and processing equipment.

[/dt_timeline_item][dt_timeline_item position=”right”][mvc_infobox title_color=”#000000″ info_title=”High Torque Rotary Machinery Assembling” title_size=”30″ image_id=”1788″ image_size=”200″][/mvc_infobox]

Development and building of high torque/low-speed rotary assemblies.

[/dt_timeline_item][dt_timeline_item][mvc_infobox title_color=”#000000″ info_title=”Turbo Machinery Assembling” title_size=”30″ image_id=”1788″ image_size=”200″][/mvc_infobox]

High dynamics turbo machinery assembly.

[/dt_timeline_item][dt_timeline_item position=”right”][mvc_infobox title_color=”#000000″ info_title=”Thermal Machinery Assembling” title_size=”30″ image_id=”1788″ image_size=”200″][/mvc_infobox]

Assembly of high capacity heat exchanging equipment for solid/solid, gas/solid, liquid/solid combinations.

[/dt_timeline_item][dt_timeline_item][mvc_infobox title_color=”#000000″ info_title=”Hydraulics & Pneumatics Power Unit Assembling” title_size=”30″ image_id=”1788″ image_size=”200″][/mvc_infobox]

Assembly of hydraulic and pneumatic power units for driving our moving floor silos, disintegrating rotors, shredders, etc.

[/dt_timeline_item][dt_timeline_item position=”right”][mvc_infobox title_color=”#000000″ info_title=”Hydraulics & Pneumatics Mechanism Assembling” title_size=”30″ image_id=”1788″ image_size=”200″][/mvc_infobox]

Assembly of hydraulic and pneumatic mechanisms for driving our moving floor silos, disintegrating rotors, shredders, etc.

[/dt_timeline_item][dt_timeline_item][mvc_infobox title_color=”#000000″ info_title=”Electromechanical Components Assembling” title_size=”30″ image_id=”1788″ image_size=”200″][/mvc_infobox]

Assembly of electromechanical units for driving and position controlling of our disintegrating and shredding rotors, rolling mills, elevation units, etc.

[/dt_timeline_item][/dt_timeline]